SpinChem

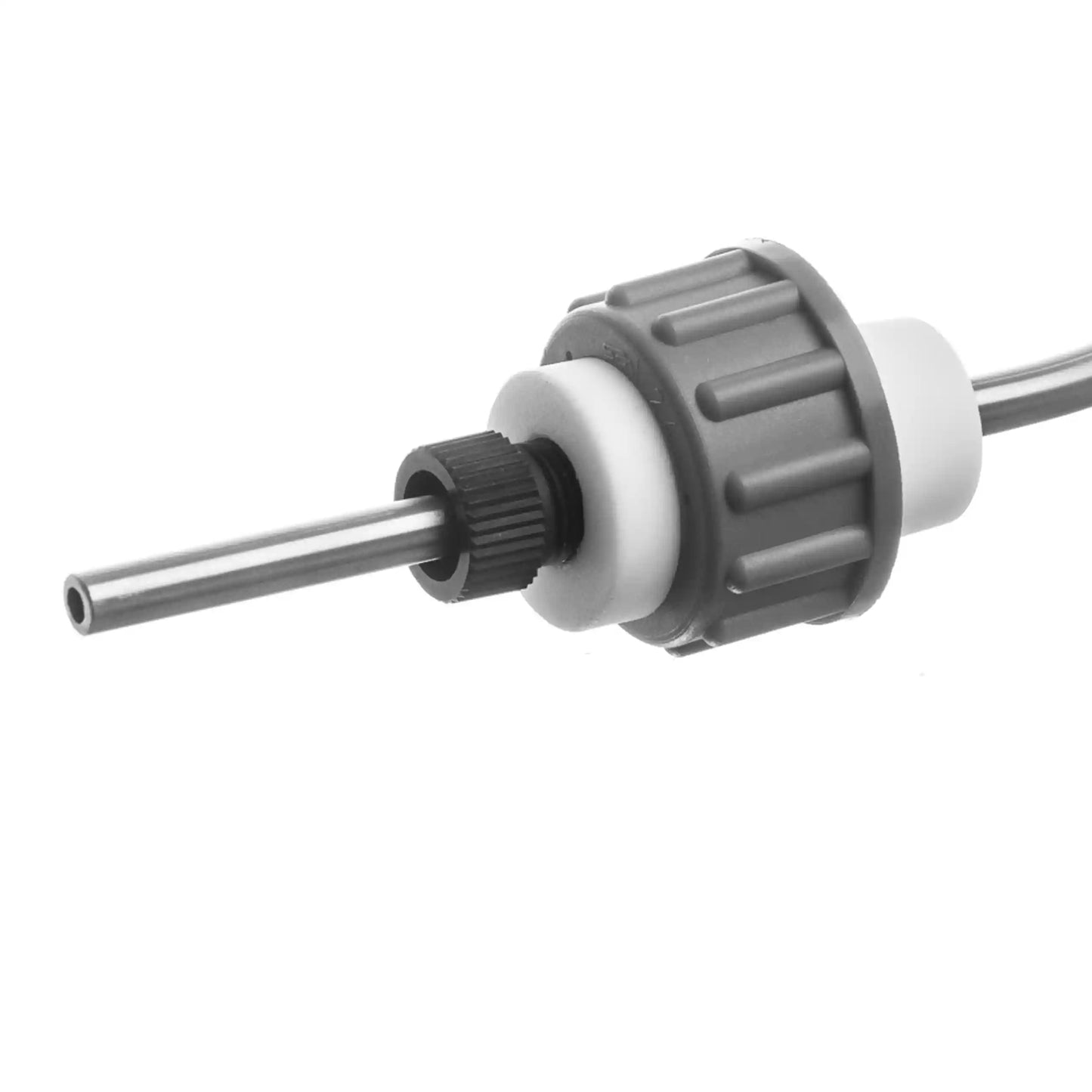

SpinChem® Gas sparger

SpinChem® Gas sparger

SpinChem® Gas Sparger improves reaction kinetics in gas-liquid processes, facilitating aerobic enzymatic reactions and pollutant degradation.

Constructed from chemical-resistant materials for reliable performance.

Suitable for Vessels V2 and V3.

SKU: 2910-401

Couldn't load pickup availability

Share

Specification

Specification

- Material: Stainless Steel (SS316L, EN2348), PTFE

- Weight: 120 g

Applications

Applications

Applications

The SpinChem® Rotating Bed Reactor (RBR) enhances many aspects of heterogeneous processes, making it ideal for:

Research & Industry:

Easy reaction scale-up without performance loss.

Nuclear Wastewater Remediation:

Efficient nuclear effluent management and waste reduction.

Environmental Engineering:

Versatile pollutant degradation, pesticide removal, and wastewater remediation, including PFAS removal.

Biocatalysis:

Improved catalyst lifetime and economic viability of immobilized enzymes.

Chemical Catalysis:

Enables heterogeneous catalysis for synthesis of fine chemicals and active pharmaceutical ingredients (APIs).

Decolorization:

Resource-efficient use of activated carbon for removing colorants from wastewater, chemical products, extracts, and oils across industries.

Tech Insights Blog

-

The importance of baffles in a reactor vessel

Discover how baffles revolutionize reactor vessel performance. Learn about enhanced mixing efficiency, vortex prevention, and optimized mass transfer in chemical processes. Essential reading for process engineers and chemical researchers.

The importance of baffles in a reactor vessel

Discover how baffles revolutionize reactor vessel performance. Learn about enhanced mixing efficiency, vortex prevention, and optimized mass transfer in chemical processes. Essential reading for process engineers and chemical researchers.

Revolutionize your reactions

Due to its smart design, the SpinChem® RBR not only helps to transform fluids at a molecule level, but also addresses operational inefficiencies and environmental challenges.

- Short Reaction time

- Long Catalyst Lifetime

- No filtration required

Looking for resource-efficient solutions?

Turn your chemical processes into scalable, sustainable, and resource-efficient solutions that maximize yield while minimizing environmental and health impacts.

-

Simple to scale

The SpinChem® RBR enables consistent and predictable results across scales with solutions possible for processing liquids from 150 ml up to thousands of cubic meters.

-

Versatile

RBR technology accommodates various heterogeneous reactions with diverse solid phases. Its flexible design allows for seamless integration into existing production lines and processes.

-

Cost-efficient

Applying the RBR technology results in more efficient processes, reduced cycle times, and decreased energy consumption, making it an attractive investment for industries seeking to optimize their chemical processes.